What Does Aws Cwi Mean?

Table of ContentsOur Aws Cwi DiariesThe Ultimate Guide To Aws CwiEverything about Aws Cwi5 Simple Techniques For Aws CwiUnknown Facts About Aws Cwi

It should be kept in mind that many jobs do not have demands for utilizing qualified inspectors and many business use their "finest" welders for this role. While this might operate in some instances, it is definitely dangerous and it has numerous defects, some apparent and some not so apparent. PFS developed a program where all Welding Inspectors are certified in accordance with ASNT SNT TC-1A and AWS QC1 Licensed Welding Inspector.

The role of All PFS welding examiners start prior to the welding equipment is even changed on. PFS Welding Examiners are trained to inspect the adhering to before welding starts: Welder is qualified. Base material is appropriately clean prior to welding.

Aws Cwi for Dummies

The WPS variables are being followed by the welder. PFS Welding Examiners then investigate all welding procedures throughout the manufacturing procedure to make certain that all demands are being fulfilled. The advantages of making use of Certified Welding Assessors: ASNT and AWS Welding assessor certification has been widely approved by the United States and even a lot of the significant industrial countries in the globe.

Quality welding and very trained licensed welding inspections directly affects not just the efficiency of the item yet the security, life span and dependability of the process that the welded element is part of. One element of this, the Licensed Welder, is not nearly enough to guarantee success just like any procedure, an independent collection of eyes that are trained to create an appropriate training process along with a reliable and effective recorded monitoring system as given by a Licensed Welding Inspector, finishes the top quality control that ensures that the client is supplied the very best possible quality constructed and documented product.

Do not be shocked that a lot of top-level sectors will certainly need you to employ licensed welding inspectors to oversee welding - https://us.enrollbusiness.com/BusinessProfile/6859290/AWS%20CWI. This is done to reduce danger in what is commonly seen as a rather risky market. An in-house qualified welding inspector will be able to make certain that your task is tailored to all the demands of appropriate welding codes, guaranteeing its quality

Things about Aws Cwi

They'll likewise begin the process by carrying out testing activities like welder performance qualification testing and welder procedure credentials testing. This generally needs some weeks to complete and require to be examined and authorized before the onset of clients welding projects. This ensures the competence of those servicing your task.

Qualified internal welding assessors offer that careful eye. They will help you by getting rid of variability during the welding processes (https://www.startus.cc/company/aws-cwi). This in turn will benefit you with a quicker result and decreased manufacturing expenses at the end of stated process, enabling you to do more with the sources that you currently have

These consist of ductility, joint geometry, wire feed speed, arc current, arc voltage, base metal chemistry, securing gas type, filler metal chemistry, and tensile strength among others. It is necessary that you think about the worth of having a licensed welding examiner before you start any type of job. After all, there is an actual worth in having a skilled testimonial your project before you even strike the first arc.

9 Simple Techniques For Aws Cwi

A certified welding assessor will have had years of experience which your business will certainly be able to draw from. They will have seen various risks and successes and the lessons they have learned from them will certainly assist your company to stay away from pricey reworks. This is why it is very important to locate a welding business with a seasoned and very educated in-house qualified welding assessor on staff.

Something failed. Wait a minute and try once more Try again.

Because 1919, American Welding Culture requirements, solutions, and programs have actually sustained the guys and women of welding in the USA. Today AWS is honored to state that our influence extends the globe, and we sustain countless welding professionals worldwide. To help our international participants, AWS contracts with companies in countries throughout the world to facilitate qualification exams.

This approach of experience-based learning helps welders in training comprehend technological market requirements and terminology while obtaining critical hands-on abilities. Supplying this type of training indicates trainees require superb aid from qualified experts.

What Does Aws Cwi Mean?

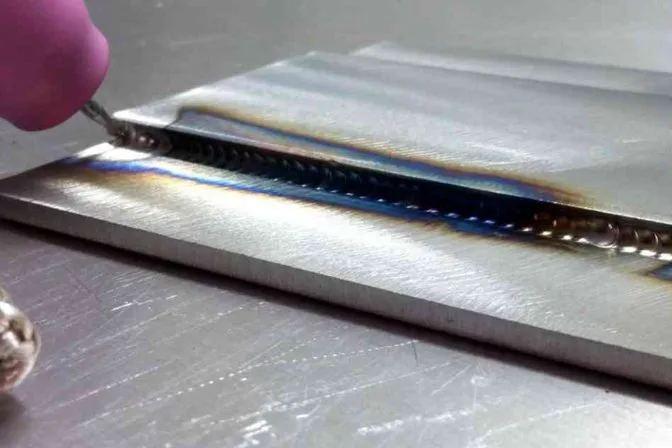

Our weld evaluation procedures aid to confirm the quality and accuracy of welds, while testing methods assist to recognize incongruities and inadequacies. These procedures incorporated influence improved job efficiency along welders. OXARC's varied range of welding processes our specialists can test is comprehensive with procedures like: Shielded steel arc welding (SMAW) Gas tungsten arc welding (GTAW) Flux core arc welding (FCAW) Gas steel arc welding (GMAW) We can also execute credentials and accreditation examinations on plate, pipe, stainless steel and various other particularly asked for materials.

Expert management, quality product or services and dedication to our market maintain OXARC offering our clients with more helpful hints the items and remedies they need. Our staff has a direct line of communication with the professionals in welding such as Lincoln Electric, ESAB, Avesta Stainless, Stoody, Select Arc, Eutectic and Thermal Arc, making our solutions an excellent selection for diverse markets.